As the core driving equipment of modern production in paper mills, frequency converters form deep synergy with papermaking process through intelligent power control technology, significantly improving the energy efficiency, stability and intelligence level of production systems.

Compared with traditional control methods, frequency converters have the following advantages:

- Energy saving and high efficiency: optimize motor power output and reduce energy consumption by more than 30%

- Precise speed regulation: achieve precise synchronization of speeds of each section of the paper machine (±0.1% accuracy)

- Reduce mechanical loss: soft start/stop function extends equipment life

- Intelligent control: integrated PLC realizes automatic tension adjustment and fault diagnosis

Especially suitable for key sections such as pulping machine, calender, winder, etc., significantly improves paper quality and production efficiency, and is the core equipment for energy-saving transformation of modern paper mills.

Related Product

Solutions List

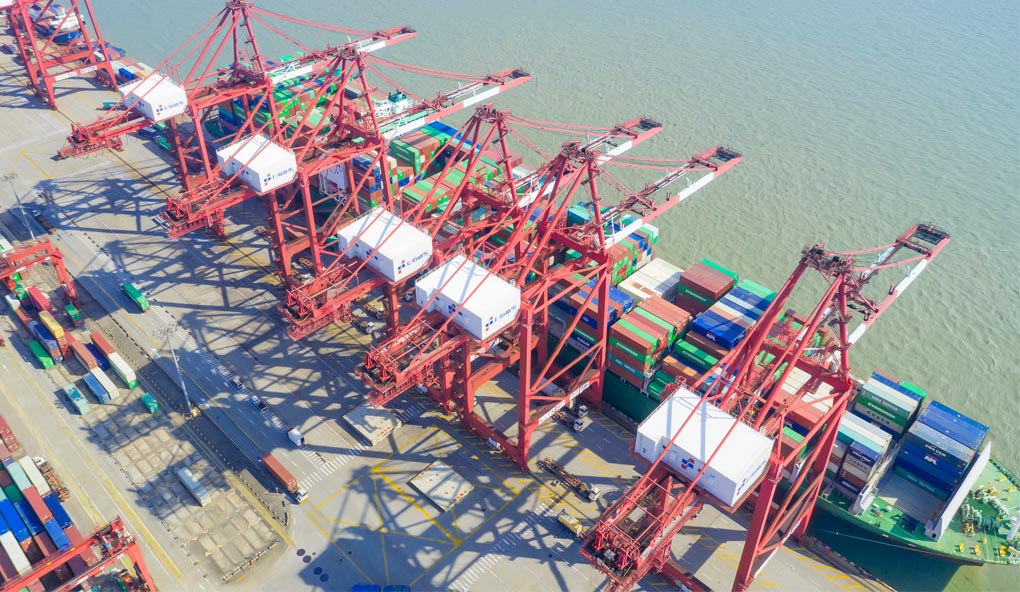

Variable frequency drive is a key device in the manufacturing industry, which achieves precise control and efficient energy saving by adjusting the motor speed.

Variable frequency drive optimize motor control in power systems by adjusting voltage and frequency, enhancing efficiency and reducing energy use by 20-50%.

Variable frequency inverter accurately controls the speed and torque of the crane by adjusting the voltage and frequency, significantly improving operating efficiency, controllability and safety.