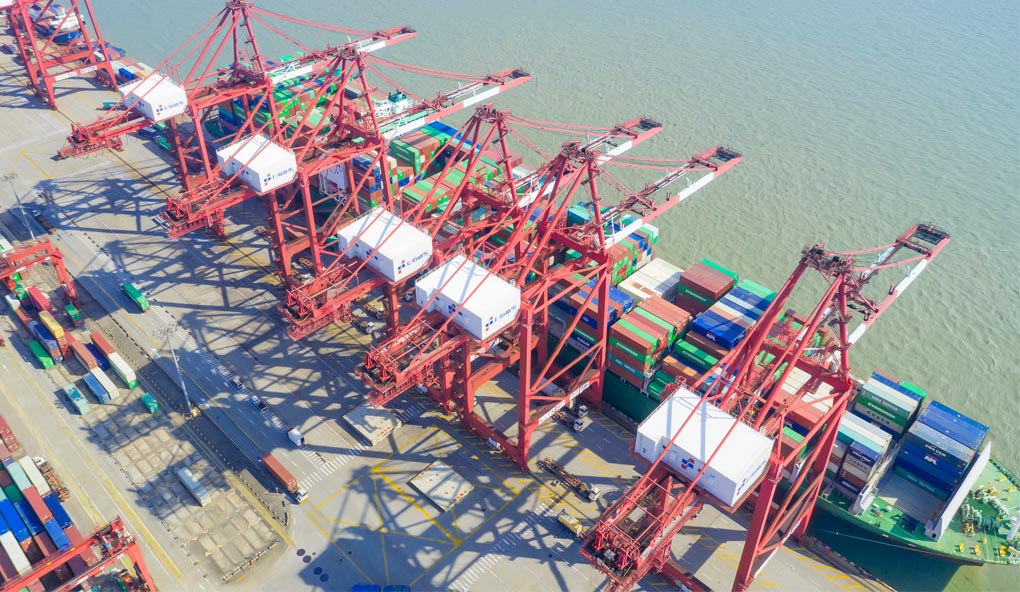

VFDs play a crucial role in recycling crane systems, which typically consist of a VFD, electric motor, braking unit, and control system. The VFD intelligently regulates motor speed and torque to optimize material handling operations for scrap metal, waste processing, and recycling applications.

Key Advantages Over Conventional Systems:

• Energy Efficient – Reduces power consumption by 25-40% through optimized motor control

• Precision Handling – Enables smooth acceleration/deceleration for delicate load positioning

• Adaptive Performance – Automatically adjusts torque to handle variable scrap weights

• Reduced Wear – Minimizes mechanical stress on hoists, cables and gears

• Smart Control – Features overload protection and real-time monitoring capabilities

With their ability to operate reliably in dusty, harsh environments, VFD-equipped recycling cranes are particularly valuable for Scrap metal yards, Waste processing plants, Demolition material recovery sites.

The technology significantly improves operational efficiency while lowering maintenance costs, making it an ideal solution for modern recycling facilities.

Related Product

Solutions List

Variable frequency drive is a key device in the manufacturing industry, which achieves precise control and efficient energy saving by adjusting the motor speed.

Variable frequency drive optimize motor control in power systems by adjusting voltage and frequency, enhancing efficiency and reducing energy use by 20-50%.

Variable frequency inverter intelligently controls the recycling crane, saving more than 20% energy, accurately preventing sway, and extending the service life by 40%.