The inverter is the core control device of the conveying crane system. It can achieve precise control of material transportation by intelligently adjusting the motor speed and torque.

As the core drive unit of the conveying crane, the inverter can achieve precise control of material transportation by intelligently adjusting the motor speed and torque. It has three core values:

- Dynamic energy saving (reducing energy consumption by 25-40%), reducing mechanical impact through soft start-stop and load adaptive technology;

- Intelligent operation and maintenance, integrating overload protection and fault diagnosis functions, extending equipment life by more than 30%;

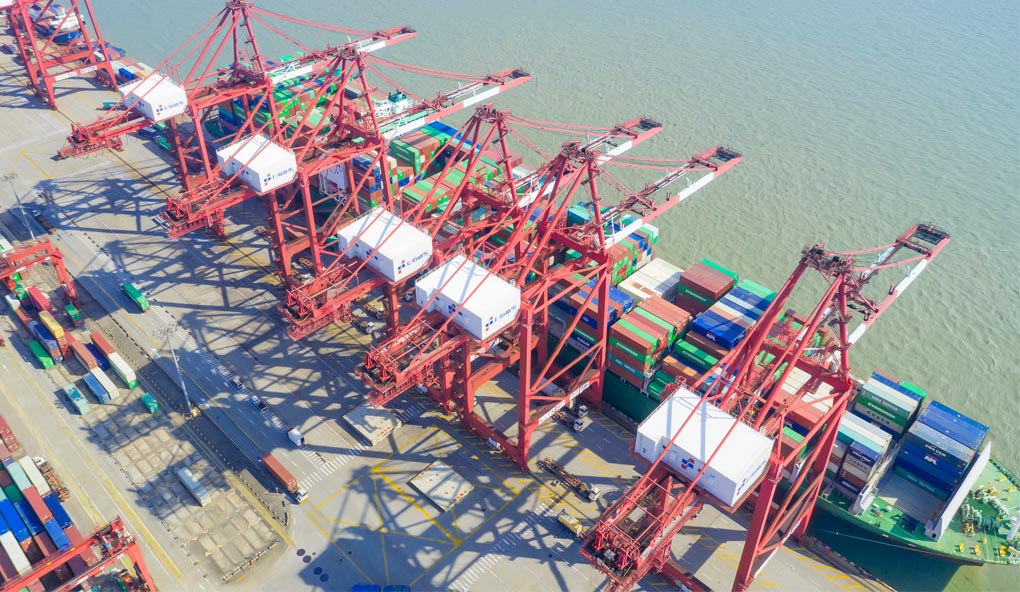

- Process optimization, supporting multi-speed precise matching of different materials (such as ore/container) transportation requirements, especially suitable for continuous operation scenarios such as port loading and unloading and mining, and can improve comprehensive energy efficiency by 50% compared with traditional fixed speed drive systems.

The system consists of inverter, drive motor, conveying mechanism and intelligent control system, which can be widely used in port loading and unloading, mining transportation, factory logistics and other scenarios.

Related Product

Solution List

As the core control equipment of the paper production line, the inverter can significantly improve the operating efficiency of paper machines, fans and other equipment by intelligently adjusting the motor speed.

Variable frequency inverter intelligently control steel mill equipment, saving 20%-40% energy, improving efficiency and reducing consumption. It is the core driving technology of smart steel plants.

Variable frequency inverter accurately controls the speed and torque of the crane by adjusting the voltage and frequency, significantly improving operating efficiency, controllability and safety.