Description

BR100 Variable Frequency Drive Overview

BR100 mini AC drive embodies the latest in high-performance frequency inverter technology, catering to modern industrial demands. With features like speed & torque control, slip compensation, energy-saving, and auto-tuning, it excels in driving diverse asynchronous motors. Designed for small size and high efficiency, BR100 boasts high capacity, power density, EMC compliance, and unparalleled reliability. Perfect for automation, pumps, fans, and more, it’s a compact yet powerful solution for today’s industries. BR100 Variable Frequency Drive

Features

- With open-loop vector drive function, it can realize low-speed and high-torque application scenarios.

- The heat dissipation duct is fully sealed, with strong environmental resistance, good heat dissipation effect and excellent performance.

- V/F control, large torque output, strong starting ability with load.

- Suitable for multi-scenario mode applications (such as smart small water pumps, engraving machines, etc.)

- More than 80% of the control performance can be achieved without learning.

- Suitable for multi-scene mode applications (such as smart small water pumps, engraving machines, etc.)

- Complete protection functions, including output phase loss, overcurrent, overvoltage, overload, overtemperature and other functions, to ensure the safety of motors and inverters to the greatest extent.

- Added braking, RS485 bus communication, temperature protection, etc.

Product Characteristics

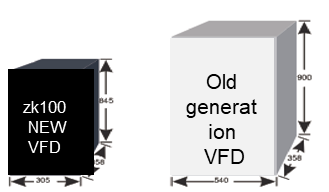

1. Refined design volume

– ZK100 VFD compared to peers: same power output, reduced volume by 30%

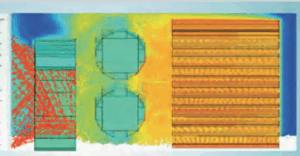

2. Independent ventilation channel design

– Completely independent air duct design prevents pollutants from entering the electronic components area, improves product protection effect, and adapts to various environments

– The upper chamber side and top surface are designed without ventilation holes, which effectively prevents the entry of pollutants while ensuring temperature rise, and truly realizes upper and lower isolation.

– High loss devices, bus electrolytic capacitors are fully heat dissipated

– Adopts high-speed, double-ball DC fan with long service life

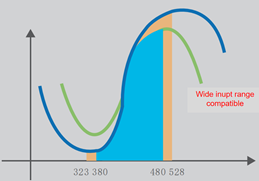

3. Wide range of grid adaptability

– Wide voltage design in compliance with international standards

– Meets the fluctuation range of 220V/380V/480V-15%~+10% including Europe, North America, India and other countries

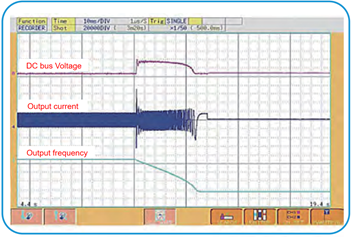

4. Overcurrent and overvoltage stall suppression

– By self-adjusting the output frequency and output voltage of the inverter, to maintain the DC voltage of the inverter at a fixed level to prevent overcurrent and overvoltage

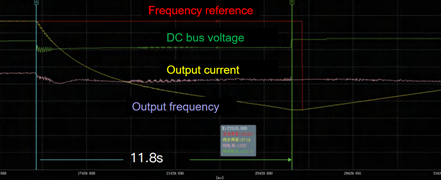

5. Anti shaking function

– When the power supply suddenly loses, there are two options for handling it.

– It can effectively protect the safety of equipment in some situations where coasting is not allowed.

– In the event of power grid fluctuations or instantaneous power outages, the driver uses a superior under voltage suppression algorithm to ensure that the system can maintain normal operation for the longest time under the same inertia load.

6. Efficient & Energy-saving

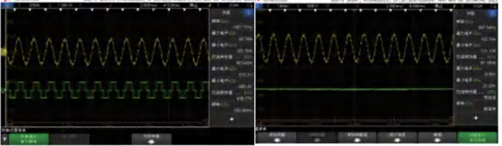

– Excellent energy-saving control algorithm, small current and high efficiency.

– Direct drive control, no energy loss from reduction box and gear transmission.

– Under the same load, We zk100N output current is smaller, more energy-saving and more efficient, especially the field weakening area control PK other big brands as show above Fig.

Application

● Metal, CNC machine, Wire drawing machines and other mechanical equipment, kinds of AC pumps ● Agriculture irrigation, solar water pumping system

● Boiler drum, Induced fan, Counter-rotating fan, Blower ● Kinds of machine with motor drivings

● Kinds of AC pumps, fans… ● Paper making, Chemical, Pharmaceutical, Textile etc

Technical Specifications

BR100 Variable Frequency Drive

| Items | Specification | ||

| Control mode | Control mode | SVC in open loop | V/F control

|

| Starting torque | 0.5Hz 180% | 0.5Hz 150% 0.00Hz 180% | |

| Speed stabilizingprecision | ±0.5% Maximum speed (SVC) | ||

| Motor type | General induction motor | ||

| Function design | Overload capacity | G-type machine: 110% long term; 150% 1 minute: | |

| frequency resolution | Analog setting: 0.025% of the maximum frequency Digital setting: 0.01Hz | ||

| Carrier frequency | 0.5K~16KHz, the carrier frequency can be adjusted by temperature automatically | ||

| Frequency reference setting method | Digital of Control panel, analog AVI, ACI, potentiometer of control panel, UP/DN control, communication, | ||

| Acceleration./deceleration characteristic | Linear curve and S curve accel. /decel. mode, range of time: 0.0 to 65000S. | ||

| V/F curve | 3 mode: linear, multiple points, N Power | ||

| V/F separation | 2 times separation: totally separation, half separation | ||

| DC braking | DC braking frequency: 0.0 to 300Hz, DC braking current: 0.0% to 100% | ||

| Braking unit | Standard built in for up to 4T22G (22kw), optional built it for ~4T75G (30kw to 75kw), external built for above 4T93G (95kw). | ||

| Jog function | Job frequency range: 0.0 to 50.0Hz, the accelerationand decelerationtime of Jog | ||

| Configure PIDfunction | Easy to perform pressure, flow, temperature close loop control. | ||

| PLC multiple speed | To achieve 16 segment speed running through built in PLC or terminal control | ||

| Common Dc bus | Multiple drivesuse one DC bus for energy balance. | ||

| Auto voltage regulation (AVR) | Enable to keep output voltage constant when grid fluctuation | ||

| Over load tolerance capability | G type model: 150% rated current for 60s, 180% rated current for 3s, P type Model: 120% rated current for 60s, 150% rated current for 3s. | ||

| Stall protectioncontrol when over current, over voltage | Carry out limiting automation for running current, voltage to prevent over current, over voltage frequently | ||

| Rapidcurrent limit function | Minimize the IGBT module broken to protect the AC Drive, maximum reduce the over current fault. | ||

| Torque limit and torque control | “Excavator” characteristics , torque limit automatically during motor running. Torque control is available in close loop vector control mode. | ||

| Features | Friendly interface | Display “Hello” when power on. | |

| Multiple function key JOG button | It can set for Forward Jog, reverse Jog, forward/reverse switch | ||

| Timing control function | A total running time and total running time calculating | ||

| 2 group motor parameters | To achieve two motor switchoverfreely, control mode is selectable | ||

| Motor over heat protection | Accepting motor temperature sensor signal input via AI1 terminals. | ||

| Multiple kinds encoder * | Compatible collectorPG, differentialPG, and rotary transformerEncoder( resolver). | ||

| Command source | Control panel, control terminals, series communication, switch freely. | ||

| Frequency source | Digital setting, analog current/voltage, pulse setting, serial communication, main and auxiliary combination. | ||

| Protection function | Short circuit detect whenpower on, input/output phase loss, over voltage, over current, under voltage, over heat, over load protection. | ||

| Environment | Application site | Indoor, free of exposure to sunlight, no dusty, no corrosive, no inflammable gas, no oil and water vapor, and water dipping | |

| Altitude | Lower 1000m | ||

| environment temperature | -10℃~+40℃, power derated for 40~50℃, rated current derated 1% for 1℃increasing. | ||

| humidity | Less than 95%, no water condense. | ||

| storage | -40~+70℃ | ||

| Ip rating | IP20 | ||

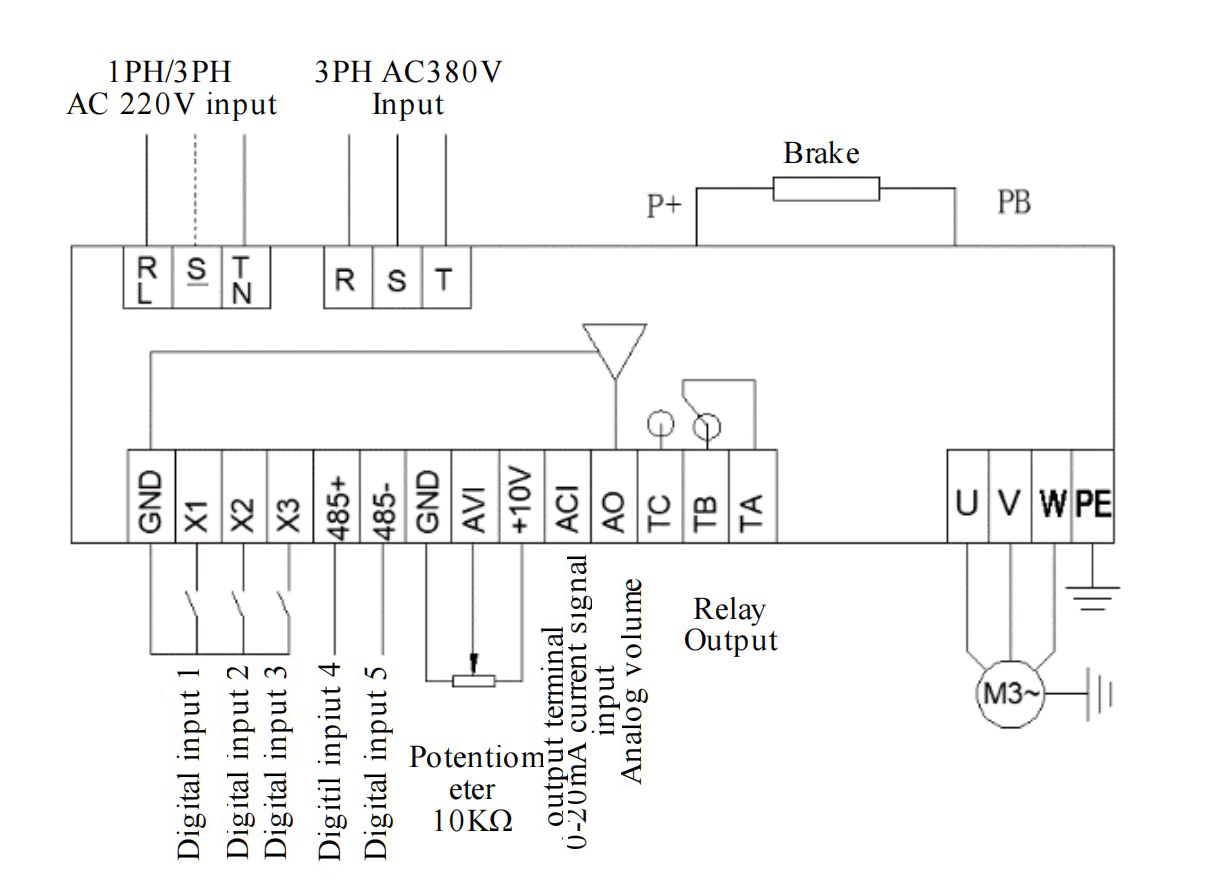

Standard Wiring Diagram

BR100 Variable Frequency Drive