Description

BR110 Series Solar Vector Inverter Overview

BR110 serise universal high-performance solar vector inverter adopts advanced current vector control technology, has wide voltage adaptability, multi-functional application, built-in braking unit and complete protection functions, and meets the efficient drive needs of industrial automation with high reliability, and is suitable for a variety of industrial scenarios. solar pumps function are optional.BR110 Solar VFD

Features

1. Excellent performance

• Current vector control algorithm, strong load capacity, fast response speed, wide speed regulation range.

2. Wide voltage input

• When the grid voltage and frequency fluctuate, the output is automatically adjusted, with little impact on motors and production machinery.

3. Wide range of applications

• It covers the application functions of various typical loads and meets the needs of various applications.

4. Built-in brake unit

• Compact structure, built-in brake unit (standard configuration for 22kW and below).

5. RS485 communication

• Standard RS485 serial communication interface, standard MODBUS communication protocol.

6. Complete protection performance

• Overcurrent, overvoltage, input phase loss, output phase loss, output imbalance detection and other protection functions.

7. High safety

• Mature and reliable structural design and highly flame-retardant materials ensure the safety of product use

8. Solar pumps function are optional

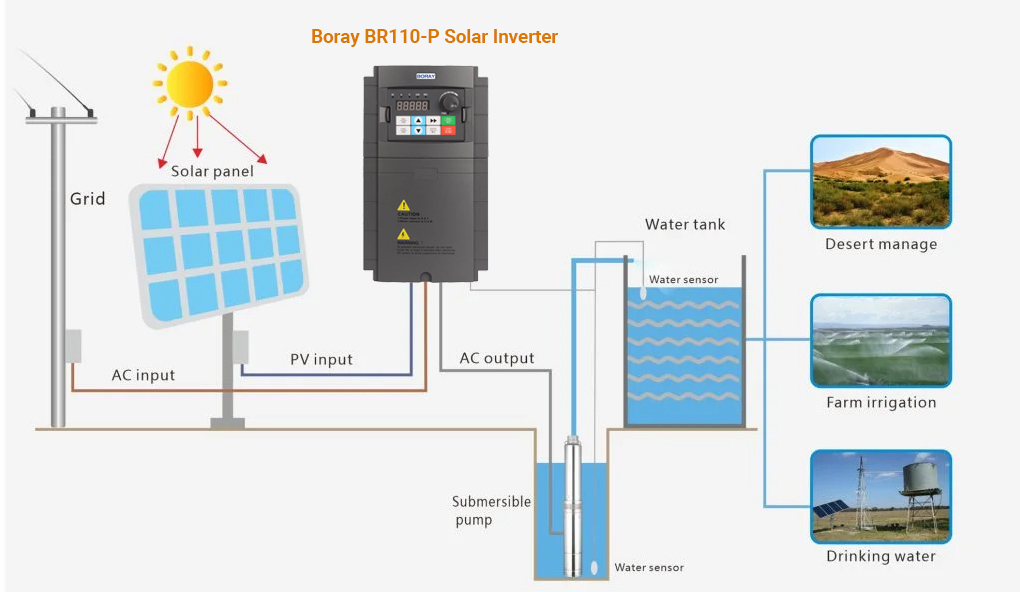

Solar Pump System

Solar pump system constitution. It includes solar panels arrays, solar pump inverter and AC pumps.

Technical Specifications

BR110 Variable Frequency Drive

| Item Description | Description | ||

| Output | Output voltage | 0V to the input voltage | |

| Output frequency | Low – frequency mode : 0.00Hz to 500.00Hz High – frequency mode : 0.0Hz to 3200.0Hz | ||

| Carrier frequency | 0.8khz to 16.0khz (automatic adjustment according to the load) | ||

| Overload capacity | 150% / 1 min | ||

| Input | Voltage/Frequency | 3-phase: 380V; 50/60Hz 1-phase: 220V; 50/60Hz | |

| the fluctuation of voltage | 3-phase: 380V AC ±15%, allowable range: 323V AC to 437V AC 1-phase: 220V AC ±15%, allowable range: 187V AC to 253V AC | ||

| Frequency range | G type: 110% for long-term, 120% for 22 min, 150% for 1min P type: 105% for long-term, 120% for 8 min, 150% for 1min | ||

| Control Character | Frequency Setting Resolution | Analog Input | 0.025% of maximum output frequency |

| Digital Setting | 0.01 Hz | ||

| Control mode | Voltage/Frequency (V/F) control, Sensorless vector control (SVC) and Feedback vector control (FVC) | ||

| Startup torque | SVC | 0.25 Hz/150% | |

| FVC | 0 Hz/180% | ||

| Speed range | SVC | 1: 200 | |

| FVC | 1: 1000 | ||

| Speed stability accuracy | SVC | ±0.5% (SVC) | |

| FVC | ±0.02% (FVC) | ||

| Torque boost | Customized boost 0.0 % to 30.0 % | ||

| V/F curve | Straight-line V/F curve, Multi-point V/F curve, Complete V/F separation and Half V/F separation | ||

| Wave current limit | In V/F mode, to achieve fast response and ensure the normal operation of the inverter | ||

| Ramp mode | Straight-line ramp, S-curve ramp Four separate acceleration/deceleration time: 0.1s to 6500s | ||

| Automatic voltage regulation (AVR) | The system maintains a constant output voltage automatically when the grid voltage changes through the permissible range | ||

| DC injection braking | DC injection braking frequency: 0 Hz to max frequency DC injection braking active time: 0.0s to 100.0s Current level of DC injection braking: 0% to 100% | ||

| Jog running | Frequency range of jog running: 0.00 to max frequency Acceleration/Deceleration time of jog running:0.0s to 6500.0s | ||

| Onboard multiple preset speeds | The system implements up to 16 speeds by using simple PLC function or by using digital input signals | ||

| Overvoltage and overcurrent stall control | Overvoltage and overcurrent stall control | ||

| Torque limit and control | The system limits the torque automatically. Torque control is applied in vector control. | ||

| Undervoltage Restrain during Running | Specially for users with a low or unsteady voltage power grid: even lower than the allowable voltage range, the system can maintain the longest possible operating time based on its unique algorithm and residual energy allocation strategy | ||

| Control input and output signals | Command source | Allows different methods of switching between command sources: Operating panel (keypad & display), Terminal I/O control and Serial communication | |

| Main frequency reference setting channel | Allows different methods of switching between frequency reference setting channels: Digital setting, Analog voltage reference, Analog current reference, Pulse reference(Optional), Communication reference | ||

| Auxiliary frequency reference setting channel | Allows fine tuning of the auxiliary frequency and main & auxiliary calculation | ||

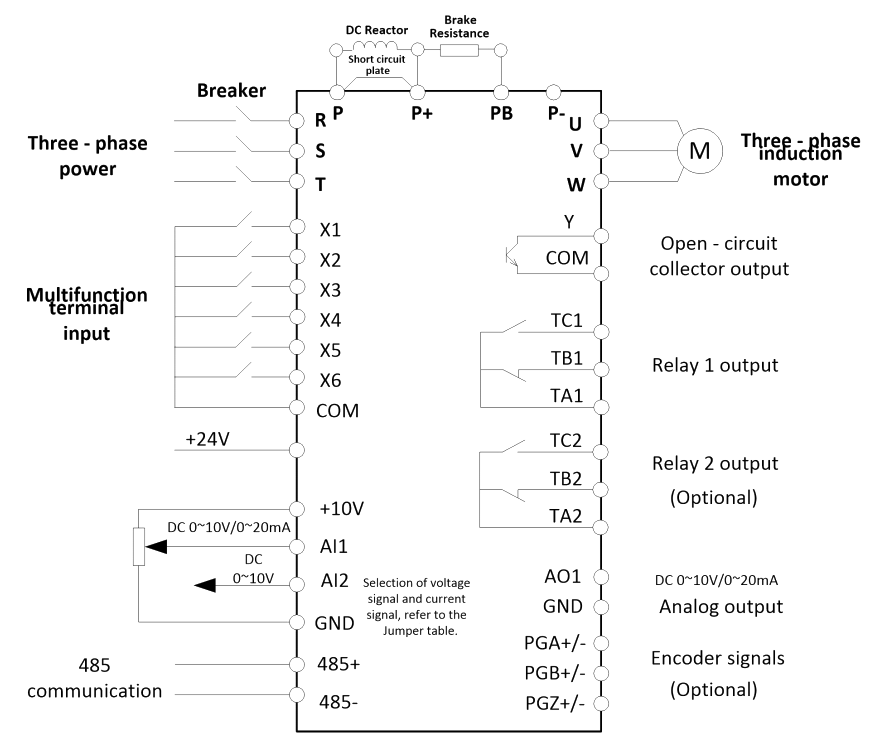

| Input terminals | 0 to 5V keyboard potentiometer input Six digital input (X) terminals, one of which supports up to 50 kHz high-speed pulse inputs(Optional). Two analog input (AI) terminals, one of which supports only 0 to10 V input, and the other supports 0 to 10 V and 4 to 20 mA current input | ||

| Output terminals | Single open-collector output terminal (high-speed pulse (Optional)) for a square-wave signal Single relay output terminal Single extra AO terminal | ||

| serial communication interface | RS-485 interface | ||

| Protective Function | Overcurrent, overvoltage, undervoltage, module fault, electric thermal relay, overheat, short circuit, default phase of input and output, motor parameter adjustment abnormality, internal memory fault, etc. | ||

| Display | Five digit digital display (LED) and Status indicator light | Parameter setting: Display parameter number and value. | Function code, Data, status |

| Running state display: Display operation frequency, current, etc. | |||

| Fault display: Display the fault code. | |||

| Environment | Installation location | Install the inverter where it is indoors and protected from direct sunlight, dust and corrosive or combustible gases. Running in derated capacity above 1000m. | |

| Ambient Temperature | -10°C to +40°C (please run the VFD in derated capacity when ambient temperature is 40°C to 50°C) | ||

| Ambient Humidity | 20% to 95%RH, without condensing drops | ||

| Operation temperature | –10°C to +50°C | ||

| Vibration | Less than 0.5 g | ||

| Storage temperature | –25°C to +65°C | ||

| Installation Method | Wall-hanging type, cabinet type | ||

| Structure | Protection Level | IP20 | |

| Cooling Method | Air cooling with fan control | ||

Standard Wiring Diagram

BR100 Variable Frequency Drive